Building and Lasercutting 3D Letters

HAL/WGL student staff member Efraim Dahl started this project to build and design a decorative logo for HAL Studio, and to learn how to use the kyub software. Here are his words and documentation on the project/process:

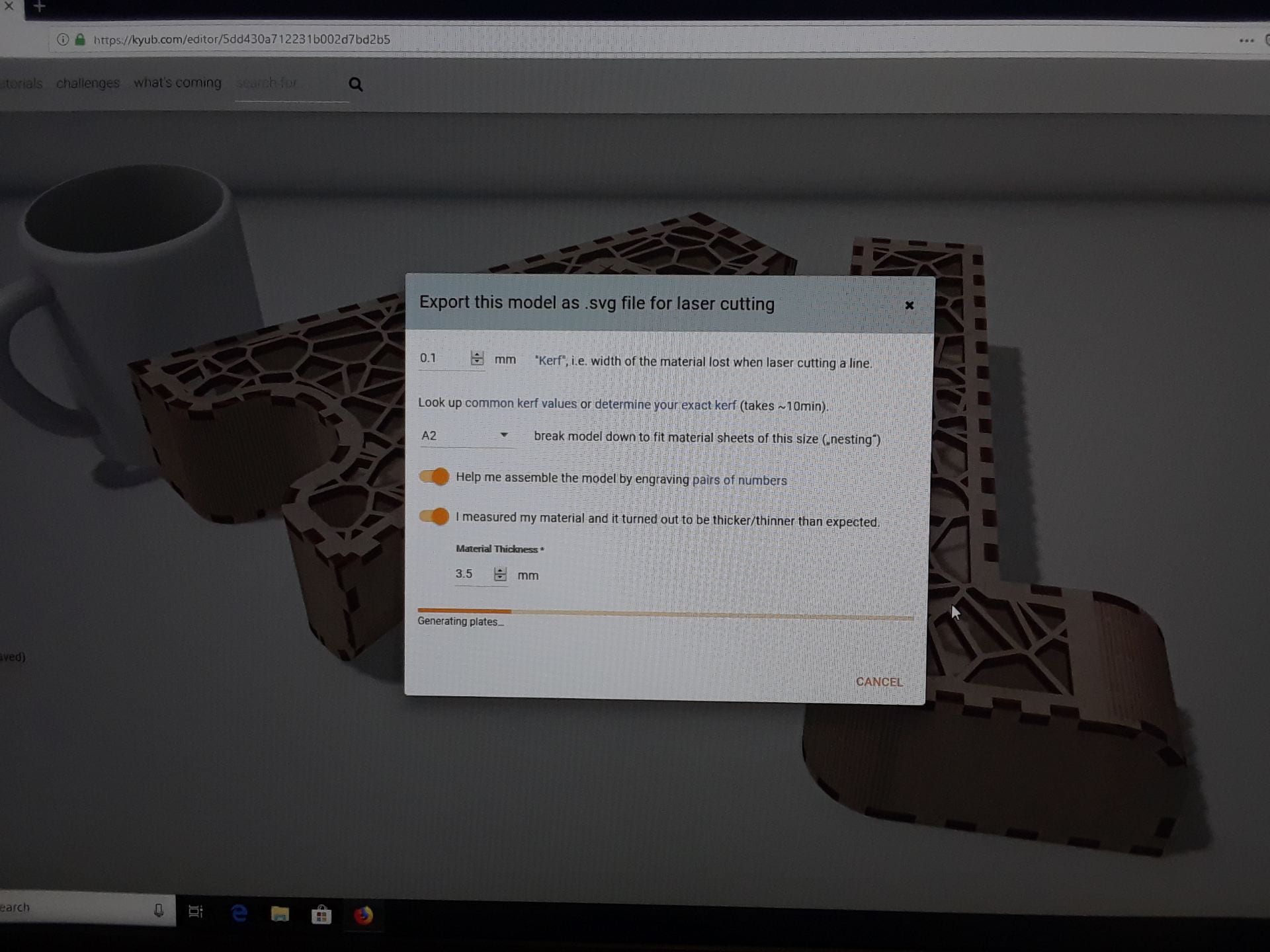

The 3D modeling is done in the kyub web-application.

This web-application is not yet publicly available and is being developed by a team at HPI in Potsdam, Germany. In the web-app you are able to assemble a 3D-model very intuitively by dragging and dropping, there are also some advanced features for rounding corners and applying custom textures and etchings. After modeling the program converts the 3 dimensional object you designed into a 2 dimensional svg-file for printing.

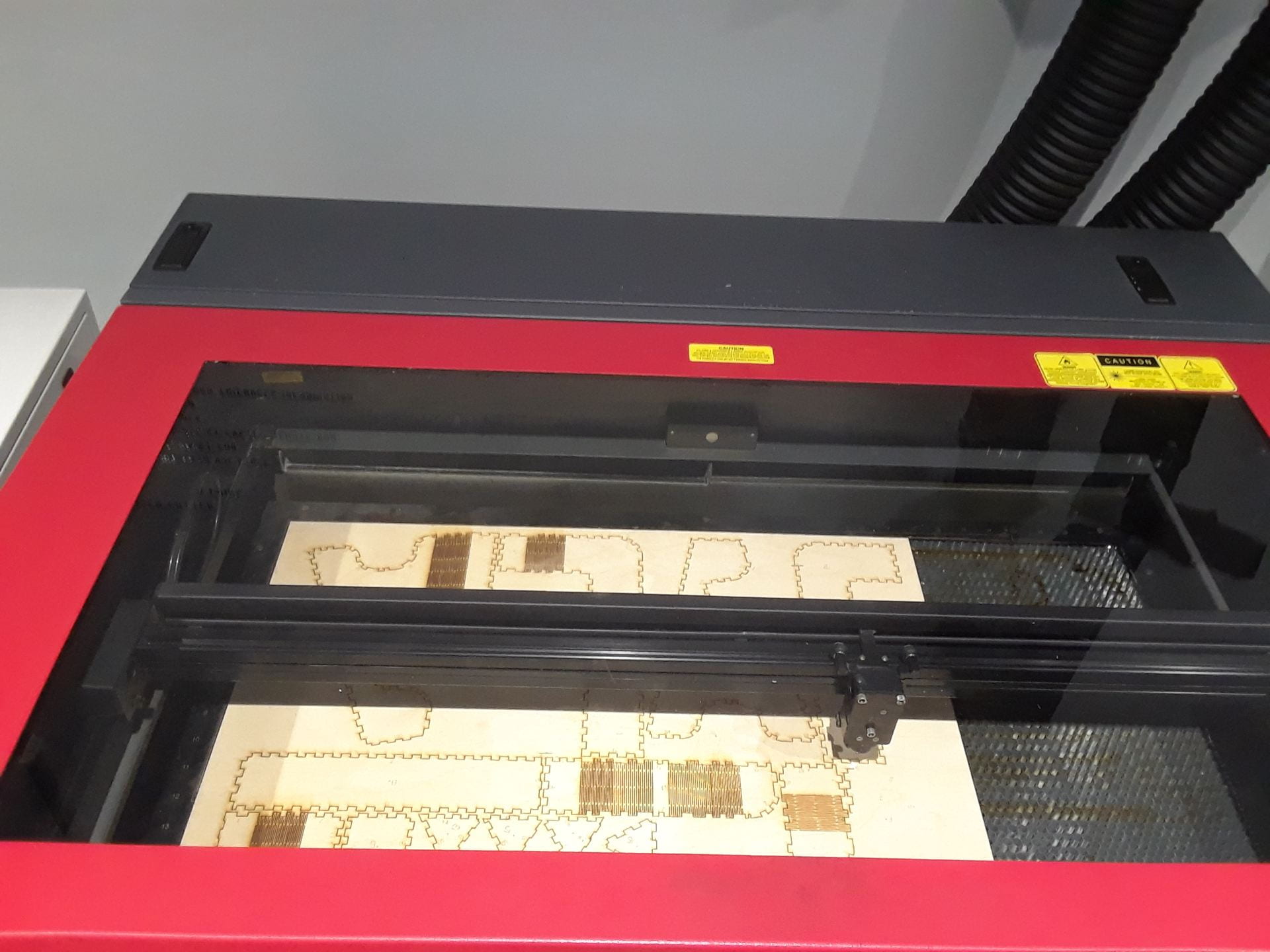

The cut will look like a 3D puzzle that you have to assemble.

Kyub conveniently numbers different parts of the print to help with the assembling of the object. No glue, or screws or any additional parts are necessary for assembling the object. The model is connected by joints that stay together by friction. That might sound unstable, but in fact the object is pretty sturdy. However, it is not always easy to assemble and a hammer (or something similar) can be useful.