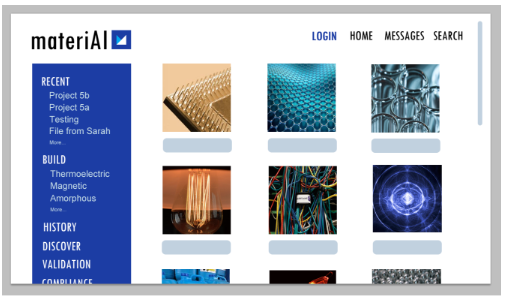

materiAI

Problem/Opportunity

Advanced materials, commonly segmented as ceramics, glasses, polymers, composites and metals & alloys, are one of the most important inputs in the design and engineering of industrially manufactured products ranging from semiconductors, consumer electronics, automobiles, and aerospace engineering. Advanced materials are essential both to the development of new products that were previously infeasible as well as improved performance of existing products (e.g. inception of the Gorilla Glass used in Apple’s iPhone screens) and more cost-efficient manufacturing of the same. The advanced materials market was estimated to have annual revenues of $42.8 billion in the US in 2015, and is expected to grow to a size of $102.5 billion by 2024.

However, significant challenges remain in satisfying the growing demand for new industrial engineering applications. Many of the materials currently used – in their natural form – are already either very rare (e.g., platinum) or very costly to extract (e.g., aluminum and titanium). The result is an exceptionally high demand for developing new advanced materials in a variety of different ways. When combined with other elements to create new materials, such as “high-strength, lightweight alloys”, the process requires precision, as even a slight difference in composition can result in performance discrepancies. As such, manufacturing companies, such as 3M and Morgan Advanced Materials, spend on average ~5% of sales on R&D, often conducting “expensive and time-consuming, trial-and-error experiments to find the right combination of components and manufacturing processes”. Given how important breakthrough materials are in enabling many nascent technologies (e.g. solar panels, electric vehicle batteries, etc.) as well as those in which there are likely to be breakthroughs in the near future (e.g. nanotechnology), there is a need for a speedier and more cost-efficient way to discover new materials.

Many people within the field believe that it is likely that big breakthroughs are likely to happen in the near-future, pointing to initiatives such as the Materials Data Repository (MDR) and the Materials Government Initiative (MGI) that have opened up massive datasets containing information about advanced materials development that are only beginning to be explored. In spite of these initiatives, most materials science academic programs do not currently include a strong emphasis on computational materials science development methods, leaving a significant opportunity for groups willing and able to specialize in those methods.

Solution

Our solution, materiAI, leverages big data and AI to map out the chemical and physical traits of different materials and forecasts how they can combine with one another. For example, MateriAI can identify properties that allow certain materials to be better at conducting electricity and absorbing energy, or to be stronger but lighter, than others. By establishing patterns and understanding relationships like these, our solution can assist researchers and materials engineers in the discovery and creation of new materials. It can sift through all possible compositions and create “recipes” that optimize for qualities, such as durability, malleability, transparency, scratch-resistance and more. In addition to composition, the algorithm can also learn about the optimal processes (e.g. melting or beating metal, at what temperatures, etc.) for desired results.

Pilot/Prototype

Similar to IBM Chef Watson’s training set, we would parse white papers, research and the internet to understand how metals react, which combinations work and how properties are created based on the attributes of the combined materials using an algorithm developed at Google called Word2vec which looks at context in which word occur. Given that material scientists have used computational modeling for years (with varying degrees of success) to suggest properties for different applications, our solution would aggregate and harness this knowledge to make more accurate predictions. To prioritize, we would start by selecting a material, such as ceramics, which has a high potential for disrupting multiple industries. With a multitude of requirements for different types of properties based on the industry our technology would be extremely useful in tailoring the material based on the industry. Automobile manufacturers leverage the thermal and electric properties of ceramics and may not require it to be porous, substituting the porosity for ideally a strengthening component. This may not be the case when used in the medical equipment industry wherein its reaction to water and body fluids is the priority. Starting out with ceramics will provide us with valuable insights across a diverse set of industries giving feedback which can be incorporated when moving into new materials specific to an industry.

Validation

To ensure our algorithm works in creating optimal combinations for new material inputs, we would want to run tests on effectiveness and market adoption. For effectiveness, we would want to make sure that our “recipes” create mixes that are at least as good as the input they are trying to replace. This would mean running tests on durability, integration with other parts, speed and ease of us, and overall quality. In terms of market adoption, we would also want to test whether a) the algorithm attracts users and b) whether the “recipes” are utilized. This would require analysis of price (willingness to pay), number of customers who purchase, number of times algorithm is used, how many “recipes” are created, how often these “recipes” are used, and how often the resulting compound is used. These data statistics would also lend itself to a feedback loop so that the algorithm can continue to improve.

Competitors

Currently, there are a few research labs at MIT and Stanford, as well as startups, such as Citrine Informatics that are taking an AI-driven approach to materials development. However, this so-called “materials informatics” approach represents a very small share of advanced materials research and development. Thus, in spite of these existing competitors, the size of the market opportunity should be large enough for a number of entrants to be successful, especially for those entrants that are able to be early-movers in the space.

Our startup will also differentiate itself from its competitors in two primary ways. First, materiAI will employ an anonymous data-sharing platform through which companies can elect to share historical research data in exchange for a reduction in price or as a means of accessing richer data from other companies that have opted in to the same. Second, Citrine Informatics has concentrated its early efforts on a handful of target verticals, namely aerospace engineering, chemicals, and consumer electronics. By focusing on different verticals such as the automotive, medical, and construction industries, we can capture an entirely different segment of the advanced materials market without significant overlap with our competitors.

Sources

https://www.energy.gov/eere/amo/articles/artificial-intelligence-future-new-materials-discovery

www.sciencemag.org/careers/2004/11/materials-science-doing-numbers

https://www.nsf.gov/mps/dmr/mse_081709.pdf

https://www.sciencedirect.com/science/article/pii/S1369702107703516

https://www.technologyreview.com/s/424631/advanced-manufacturing-and-new-materials/

http://ceramics.org/wp-content/uploads/2011/08/applications-ceramic-apps-auto-hoffmann.pdf

https://www.sciencedirect.com/science/article/pii/S1359028617300220

https://www.theverge.com/2018/4/25/17275270/artificial-intelligence-materials-science-computation

https://www.inc.com/greg-satell/this-startup-is-combining-big-data-and-materials-s.html

Team

Siddhant Dube

Eileen Feng

Nathan Stornetta

Tiffany Ho

Christina Xiong