Problem: Broken Supply Chains

A small product such as an iPhone can have thousands of different components creating a complex supply chain. Making the product is also a complex process involving setting up contracts and coordinating with numerous suppliers and distributors. During the production process, a product may travel through many different nodes. As an example, the base components of an iPhone could be made at one factory and the finishing components at another factory. When there are defects in the product, it may be difficult to pinpoint when the defect occurred or who is responsible for it because there is no secure ledger that reliably tracks every action performed during the production/supply-chain process.

In short, the often-limited transparency of where a product or component is in the supply chain can make it difficult to address issues related to loss, misdelivery, or decision-making.

Solution: Blockchain in the Supply Chain

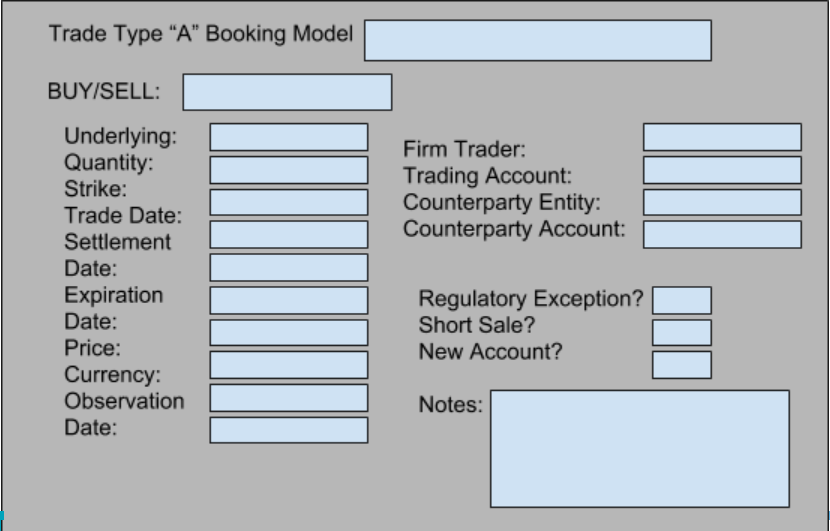

To solve these issues, our start-up will integrate blockchain technology into the tracking process of the product’s construction. As a product moves from one location to another, an entry will be made into the ledger system, which tracks when the product left the facility, what state it was in, and who handled the delivery. Once the product is received by the next party, that party will modify the block with information regarding the receipt time, state of the product, as well as any modifications that it makes. During this process a contract can be updated for the parent company to monitor that their suppliers are maintaining the agreed-upon standard of materials being used in the product.

For example, when Apple receives glass covers for their phones from a supplier, the supplier will fill in details regarding the state of the glass and the details of the transaction. Apple can then verify that the agreed-upon units are received as well as the condition they are received in. When auditing the supply chain in case of any disputes, it will be easy to see where mistakes happened and who is culpable.

Furthermore, blockchain technology would apply to both the financial transaction as well as physical transactions of products. In order to facilitate the tracking of the physical transactions, RFID or a similar technology would need to be applied to every shipment.

Ultimately, this innovation could also aid in 1) better tracking against counterfeit products, 2) ensuring compliance with regulations for all components, 3) minimizing transition costs at each stage of production and manufacture, and 4) identifying and mitigating myriad inefficiencies along the supply chain.

Pilot: Apple

In order to demonstrate the application and value of blockchain technology in complex supply chains, we propose using Apple’s iPhone as a pilot. Every component of Apple’s iPhone would be tagged, either at the individual product level or at the bulk shipment level. As components are assembled and change hands from manufacturer to manufacturer, the transactions would be tracked using blockchain technology on a permissioned ledger. As each transaction happens, both Apple and the manufacturer can enable the supporting financial transactions and smart contracting to occur as well.

Photo credit: Accenture Strategy

Value for both Suppliers and Manufacturers

End-to-end visibility and immutable smart contracts can enable value for both Apple as well as its suppliers, especially in the case of disputes. For a company like GTAT, which supplied sapphire for the screen of iPhones, a contract that is secured by blockchain might have helped save them from bankruptcy. In the original contract that GTAT had with Apple, the company was not allowed to make any modifications to the iPhones. There were also components of the contract that they did not have firm agreements on. Apple was not obligated to buy any of the sapphire GTAT made and as such, when Apple pivoted to a different supplier, GTAT had no way to make Apple buy their product. GTAT was obligated to accept and fulfill any orders by Apple for sapphire glass, but didn’t have any clause stating that Apple always needed to buy the product. GTAT ended up having to pay $439M to Apple for the right to stop supplying sapphire when Apple terminated the partnership, leaving GTAT an obligation to payback the $439M advance used to fund GTAT’s new production facility. [6]

Future

After a pilot with Apple’s iPhone, we plan on expanding to other Apple products. Once the application has proven itself with the full suite of Apple products, we would then either expand to other companies with similar businesses, such as Samsung or GE or sell this product to Apple. Ideally, we would expand to other businesses and eventually other industries with complex supply chains, including food and beverage, retail, and oil and gas.

Risks and Competition

Primary risks of this innovation are 1) that the technology is still in its infancy, 2) the complexity of the technology and its applications, 3) the decentralized nature of supply chain and logistics for electronics components and the differences in regulations and compliance in different markets where components are produced, and 4) stakeholder adoption across the supply chain will likely prove challenging.

In terms of competition, there are other start-ups emerging in this space, such as companies like the MIT-founded Eximchain [7], and Cloud Logistics. Foxconn, the manufacturer of the iPhone, has developed an early-stage blockchain prototype [8], and Samsung Electronics has a blockchain platform underway. Additionally, Amazon has undertaken projects internally that could pose competition to our product.

Sources:

[1] Deloitte: Using blockchain to drive supply chain transparency https://www2.deloitte.com/us/en/pages/operations/articles/blockchain-supply-chain-innovation.html

[2] NY Times. Blockchain: A Better Way to Track Pork Chops, Bonds, Bad Peanut Butter? https://www.nytimes.com/2017/03/04/business/dealbook/blockchain-ibm-bitcoin.html

[3] How Blockchain Will Transform The Supply Chain And Logistics Industry

[4] Blockchain for the Electronics Manufacturing Services Supply Chain

[5] Why Blockchain is a Game Changer for Supply Chain Management Transparency

http://www.supplychain247.com/article/why_blockchain_is_a_game_changer_for_the_supply_chain

[6] http://fortune.com/2014/10/29/apple-and-gtat-what-went-wrong/

[7] https://www.coindesk.com/mit-founded-startup-raises-20-million-for-supply-chain-blockchain/

[8] https://medium.com/@hermione1/foxconn-to-blaze-the-trail-blockchain-for-electronics-6742abc8aea1

Team members:

Pavlina Plasilova, Kelly de Klerk, Yuxiao Zhang, Aziz Munir, Megan McDonald