The Cytek Aurora is not the most polite instrument I know. If you fail a Quality Control test (QC) when you first turn on the instrument, it will spit out a giant FAILED error message in big red letters. For the untrained users, it can be a bit much. I can tell you it’s often uncalled for, too. What are you supposed to do? Just stop your experiment because some QC beads told you so? NEVER! Well, maybe. Look, it depends. So let’s have a quick overview of what’s involved in running QC.

Let’s start with the basics: what are we doing when we run QC? Essentially, we’re running a set of beads of different size and/or brightness. These QC beads are normally excited by all of the lasers present in the instrument and will generate a signal in each channel. And because the beads are very stable, the signal should remain the same over time. The software will use these signals to do two main tasks. The first one is to set up specific parameters on the flow cytometer and make it functional. These include figuring out the optimal voltage/gain value for each detector, as well as something called the laser delay (or how much time it takes for a cell to travel between the laser beams). The second task is to generate data that can be used to track how the instrument is performing over time. This is the data we’ll be focusing on here.

Figure 1. The Attune Performance Tracking Beads (QC) consists of a mix of beads of two different sizes and four levels of brightness.

The QC protocol examines a number of parameters on the QC beads, including a a fluorescence intensity value as well as a coefficient of variation (CV) (Fig.1). On any given day that we run QC, the acquisition software will compare these values to a baseline status to determine if the values are within an expected range. This baseline is set up by running the same beads at a time when the instrument is in top condition. Alternatively, it might just be the values provided by the manufacturer. For the QC protocol to pass, the QC beads should look as expected (in terms of fluorescence and CV) compared to the baseline values. If there is a significant divergence between the daily QC values and the baseline, the software will flag those differences (and in the case of the Cytek Aurora, yell at you in giant red letters).

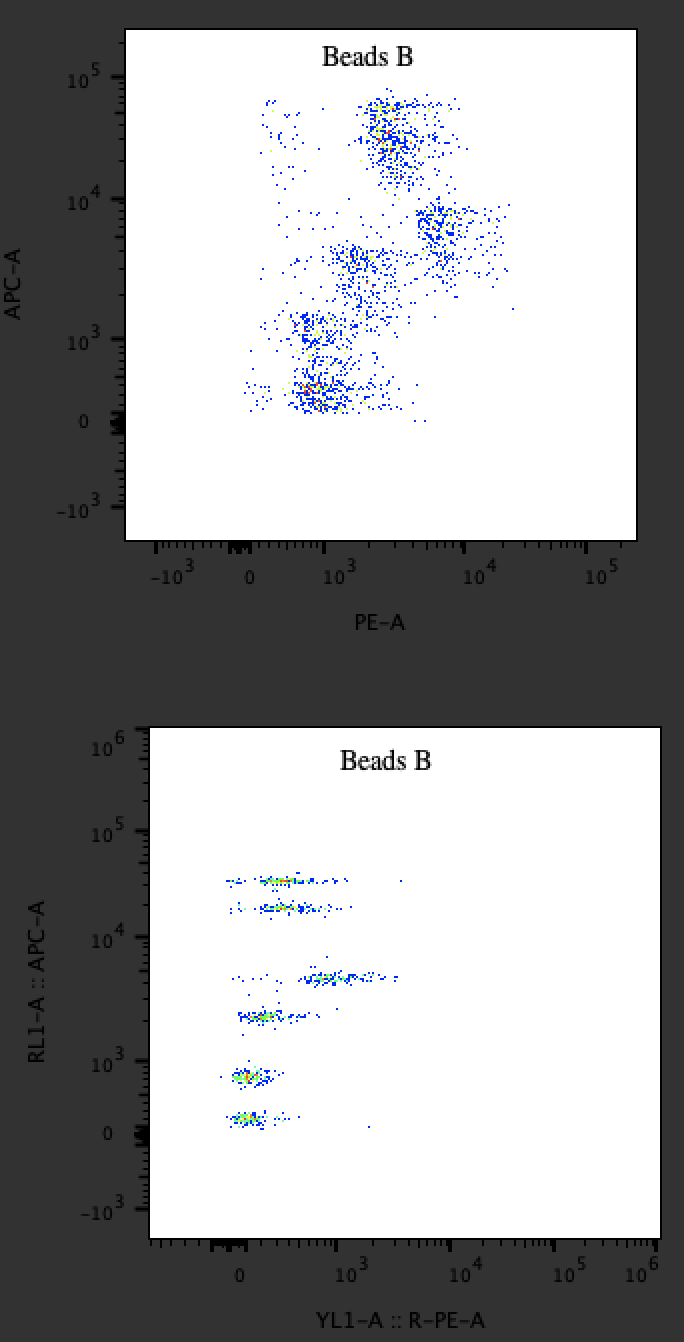

Figure 2. 6 beads of various intensities picked up by the red laser, 670/30 BP channel on two different instrument. In the upper panel, the laser is mis-aligned and the QC beads on that detector showed a high CV. The beads cannot be resolved. In the lower panel, the instrument is functioning properly and the bass have a low CV is low. All six bead populations can be resolved.

Now, a common reason you’ll trigger a warning is if the CV of one of the peaks is too high. On a flow cytometer, the CV provides an indicator of the precision of the detectors, or the dispersion of the brightness measurement of the population. A low CV value means the measurement is precise and that you are living a good life. This translates to tight populations and a good chance of resolving a dim population from a negative population on that channel. On the other hand, a high CV value means a higher variation in the measured fluorescence of the events. This translates to more diffuse populations and reduces the ability to resolve a dim population from a negative population. The example in figure 2 showcases this phenomenon.

So if you get a failure due to a high CV, do you stop your experiment? Not necessarily. There’s a few things the QC report will tell you that will illuminate the status of the instrument. Just how wide are the CVs? Are all the detectors affected? Let’s consider a few things:

1 – Re-run the QC check. You’ll get some variations from one test to the next. The results may pass on a second or third run. Don’t bother with a fourth however, at that point the solution is elsewhere.

2 – Double-check which detector is affected. If you are not using that detector, you don’t need to worry. In the case of the Aurora where all detectors are used for all fluorophores, you can focus on passing in the peak channels of each of the markers in your panel.

3 – Clean the flow cell. If the flow cells is dirty, this “dirt” will impact the way the laser hits the cells and reduce the its resolution power. There’s an easy way to figure out if the problem is coming form an unclean flow cell. When you look at the CV values for all detectors, you may note that they are all pretty high, even if only one detector failed. That would suggest that a cleaning would improve the situation. On most software, you’ll find built-in flow cell cleaning protocols that usually work pretty well.

4 – Can the laser be re-aligned? The CV is mostly impacted by the laser alignment. On most platforms, the alignment is locked in and you shouldn’t have to worry about it all that much. And if you need to tweak the alignment on a regular basis, there’s probably some underlying problem, like a fluidic issue somewhere. But for the sake of getting you through the day, can it be done? For some platforms, the CAT staff may be able to tweak the alignment of the laser optics. But be aware that the staff does not have the same toolkit (in terms of technical knowledge, and well, tools) as the manufacturer’s service engineer. Also, some instruments do not make the optical bench easily accessible. Also, if the instrument is under warranty, it’s usually a bad idea to try to fix it without the service engineer. So no promises here for an immediate fix on laser alignment.

5 – If the CV value is still fairly low, but higher than the manufacturer’s recommended value, you may be able to get away with it. If you are using this specific detector to separate a highly expressed, bright marker like CD3 from the negative population, a CV that is a hair too high should not significantly impact the data. However if the detector is being used to look at a marker that has very low expression and the fluorescence intensity is only slightly above the negative population, it may provide unusable data. A CV in double-digit may be problematic, so ask the staff if you see anything of the kind.

(Oh! Pro-tip for the Aurora users: while several detectors of any given array may be above Cytek’s recommended value, you’ll notice that only the third detector of each laser will be flagged. So failure of the third detector may indicate issues with the entire laser detector array. Now you know! Aren’t you glad you read this blog?)

There are obviously many other reasons the QC reports might be failing, ranging from poor QC bead preparation to an aging instrument that contains very old lasers. In most cases, you’ll have to stop and figure out what’s going on. And let’s be clear: using an instrument that does not pass QC is not something that you should have to put up with. The takeaway message here is that there are a few things you can try if you have a high CV, and in a pinch, a CV that is not completely off might not stop you to acquire your data. But if you notice something off about our instruments, let us know immediately!

“There’s an easy way to figure out if the problem is coming form an unclean flow cell. When you look at the CV values for all detectors, you may note that they are all pretty high, even if only one detector failed.”

My experience on BD machines is a bit different from that: A dirty flow cell affects the laser that the cells pass last the most. I assumed that the stream speed would be lower in that case and hence laser delay was imperfect. The longer the distance traveled to the specific laser’s interrogation point the higher the deviation in the delay. In at least one case, the algorithm adjusted voltage/gain instead of the delay…

Hi Christoph! This is true enough if some obstruction in the sheath line disrupts the flow in the instrument, for the reason that you describe. And at that point you would lose all signals off that laser entirely. But what I’m talking about would be a smudge in the flow cell that does not impact the fluidics. This will have an impact on your CVs.

The Fortessa does not have a built-in way to clean the flow cell. We typically have to clamp the sheath line attached to the flow cell and run detergent through the SIP, then let it sit for a while.

Hi David, thank you for your huge work here. I am reading all your articles in the blog and learning a lot of important stuff. My question is about the flow cell cleaning in the Fortessa. Could you please explain better how do you clump the sheat line? We have a Fortessa X20 in our facility and I would like to clean the flow cell, like, once a month, as a routine.

Thank you again!

Sure! We’ll do a short video about this and leave the link here – stay tuned!

Hey David, I have been following your blogs and I am having similar issues with the CV values for 1 detector. It would be very helpful if you could share the video of clamping and run detergent for a while. We have the BD LSR Fortessa.

Fair point!! We need to get back to cameras and what not. Having said that, a better option to clean your flow cell is to simply run something like contrad at a 30% dilution from your sheath tank. This will both clean the flow cell, but also the fluidics lines. Run contrad 30% for an hour, let it soak ON, and rinse it out in the morning with water.